By submitting your data, you are providing us with some level of personal information. This information is not stored on our website database. However, in order to respond to your enquiry, your data is emailed to our website’s email address where it is saved. Additionally, we may use your contact details to send you marketing material in the future. You may unsubscribe from any emails you receive following our first reply. We do not pass your data on to any third parties.

Dairy Processes

Our Dairy industry customers trust SoftTrace to support all aspects of their Dairy Manufacturing Process supporting multiple product suites such as milk, cream, cheese, butter, yoghurt, ice cream, whey, caseinate, infant formula, and ingredients production from raw material intake to product dispatch.

Our software integrates throughout the product lifecycle to offer full visibility and control at every stage of the product process flow. The SoftTrace solution provides seamless integration with plant floor automation, packing lines and in process analysis instruments capturing critical process data in real time eliminating labour intensive manual record keeping and reducing the risks associated with manual data entry.

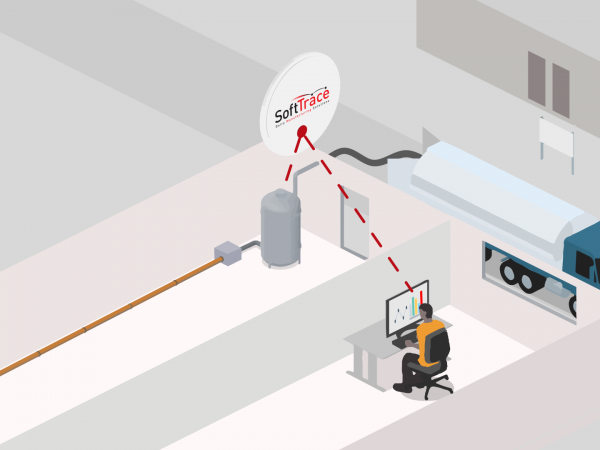

The SoftTrace system records and tracks all raw materials, ingredients received into the manufacturing facility capturing smart data from the very first point of entry to the processing facility.

- Raw Whole Milk

- Cream

- Bulk Liquid Concentrates

- Starter Cultures

- Vitamin & Mineral Concentrates

- Flavourings, Colourings, Sweeteners & Preservatives

- Product Contact packaging

- Outer packaging, labels and pallets

With integrated quality data SoftTrace provides an essential level of visibility, optimal control, rapid response and crisis management capability at intake to assist process allocation decisions based on the chemical, microbiological and organoleptic composition of the incoming ingredients

- Supplier data with road tanker ADC interface

- Load volume and mass balance calculation

- Road tanker CIP records

- Rapid antibiotic testing interface

- Out of specification alerts & notifications

- Stock reconciliation

- Management of certificates of analysis and certificates of conformance

- Supplier performance management reports

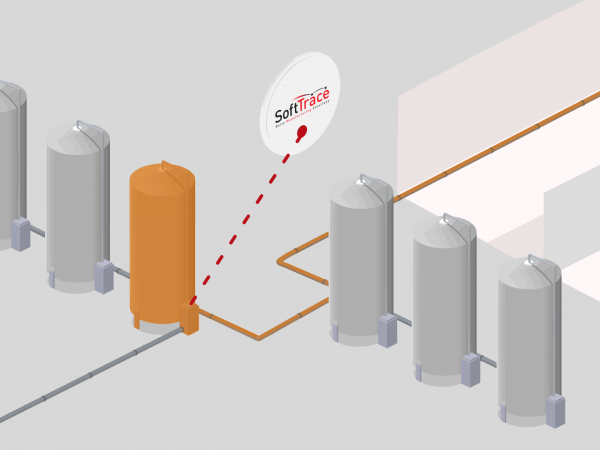

The SoftTrace system monitors the storage and allocation of inventory

- Real time data capture for informed process allocation decisions

- Silo Allocation

- Batch traceability

- Multi stage process input control

- QC analysis data for raw materials release to production

- Silo CIP cycle data capture

- Continuous flow traceability

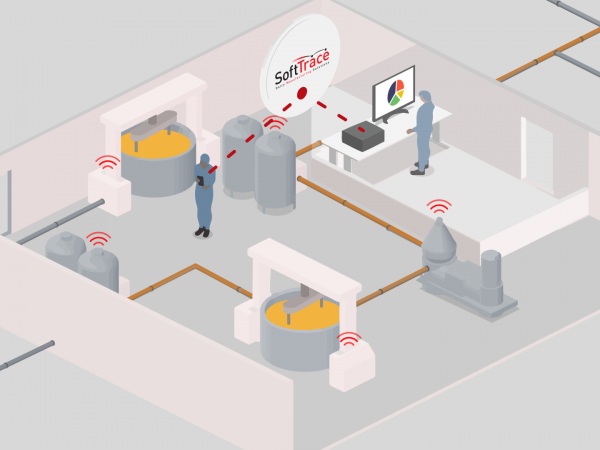

At every step of the product lifecycle SoftTrace captures the smart data linking product scheduling with sales and inventory records for the generation of:

- Manufacturing orders

- Bill of material (BOM) / ingredients lists

- Production Make Sheets

- In process records

- In line & at line product sampling schedules & analysis with instrument interface

SoftTrace seamlessly integrates and interfaces with existing on-site systems

- Integrating with plant automation and packing systems including ERP & MES

- Monitor and control product movements by volume, weight and batch code

- Easy access to full suite of QC analysis results for raw materials and in process parameters such as moisture %, total solids %

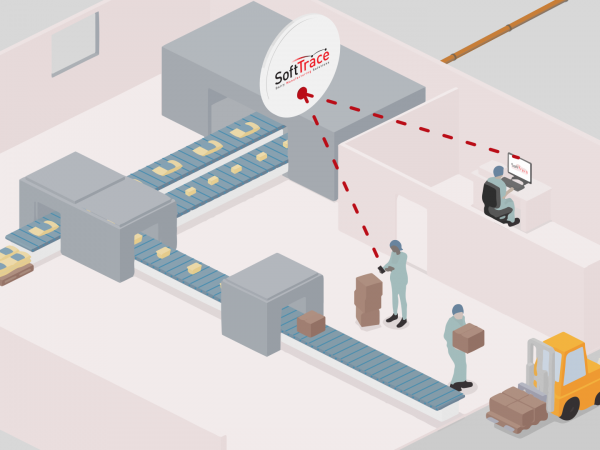

AT SoftTrace we know that once the product is manufactured maintaining control on the packing line is critical to maximising profits, and that locating and transferring stock can be costly, labour intensive and time consuming. We have designed and developed our software to automatically capture all stock movements during packing.

- Capture finished product to inventory direct from the packing line

- Capturing a unique ID bag/box/pallet to facilitate full track and trace.

- Automated label generation reconciled with stock production

- Specification overlay to maximise profits from contract fulfilment

- Integrated QC analysis profile for customer contract finished product grading allocations

SoftTrace Inventory and Transfer of Movement software ensures that you have full visibility on your finished product from the moment it comes off the packing line.

- Automated picklists

- Truck manifests

- Visual Truck Compliance Checks

- Automatic Capture of security seal/tag details

- Dispatch Documentation

- Certificates of conformance or analysis to accompany your outgoing product

The SoftTrace software solution tracks stock movement up to finished goods dispatch

- Electronic transfer of documentation to ensure your documents arrive with or ahead of your load being received to an external warehouse

- Haulier, Truck, Trailer, Load Volume, Route & Destination data capture

- Automatic confirmation of load receipt at third party/external warehouse destination

- Complete track and trace of product while in transit

Throughout the process SoftTrace Quality Management Software captures critical analysis data at every step, generating a full analysis profile and history.

- Raw Materials Intake

- Rapid Results Testing

- QC Specifications

- In process at line & in line sampling

- Environmental swabbing

- Finished goods grading

- Certificate of Analysis & Certificate of Conformance generation

- SPC Graphing & Trending of lab results

SoftTrace offers and provides clear, concise, visual reporting of the factory process end to end in minutes. Our effective suite of configurable management reports provides a transparent overview of all areas, configured to the user’s requirements.

- Raw Materials Stock Inventory

- Supplier Performance & League tables

- Stock allocations

- In Process Mass Balance calculations

- Continuous Flow Batch Traceability

- Stock Management alerts for sensitive ingredients such as Starter cultures, Vitamins & Minerals to comply with FIFO and FEFO stock control.

- Finished Product Grading reports

- Customer Specification Overlay for contract fulfilment

- Finished Goods Warehouse Stock Control

- Track & Trace from dispatch to customer warehouse.

- Full Quality Analysis reports to meet regulatory, customer and accredited standard requirements.

Who We Work With

What our clients say...

"Today the emphasis is on verification and speed. Being able to quickly demonstrate full traceability as well as rapid response capabilities is the key to gaining a competitive advantage...."

"We selected SoftTrace because of its focus on traceability and quality control, its modularity, its configurability, and the SoftTrace team’s experience in providing software to the food industry."

"It has been a pleasure to work with the SoftTrace team, they are receptive to our needs and concerns. SoftTrace have a level of food industry expertise that has..."

"Using SoftTrace MilkData we have achieved significant improvements in the general running of the laboratory. We have increased control over sample test scheduling and achieved a rapid turnaround of..."

"We chose SoftTrace because of the systems focus on the dairy industry. As the implementation progressed we became increasingly impressed with the systems flexibility and customizability. We have been..."

"We invested in SoftTrace because of its ability to improve plant efficiencies. Automating data recording, and improved performance analysis capabilities have allowed us to manage the plant more cost..."